Hi, my name is Frank Chiu, a sophomore in Product Design.

I have always been interested in how things are made, especially the process from the beginning to the final result. In my perspective, the process is the most valuable thing in my learning experience. So, I would like to share what I've experienced and what I've learned creating my project for the Sophomore Pop-up shop at the 2016 Senior Show.

I have always been interested in how things are made, especially the process from the beginning to the final result. In my perspective, the process is the most valuable thing in my learning experience. So, I would like to share what I've experienced and what I've learned creating my project for the Sophomore Pop-up shop at the 2016 Senior Show.

In this particular project, my partner, Andrea, and I planned

to mass-produce a product by utilizing a cast molding technique.

The cast molding method is a molding technique in which a liquid material is poured into a mold, solidified into a cast, then ejected out of the mold to complete the process.

The cast molding method is a molding technique in which a liquid material is poured into a mold, solidified into a cast, then ejected out of the mold to complete the process.

Initially, we had the idea of creating a teapot (Image 1) that has an

interesting base design where a candle can be placed underneath to keep it

warm.

Meanwhile, to promote our pop-up shop, we created an

Instagram account, fc_product, uploading the process shots.

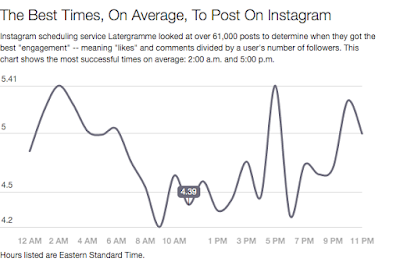

We also did some research for when the best time is for posting pictures and decided to post one picture every Wednesday, at noon, which is the time and day that has the most viewers on Instagram.

We also did some research for when the best time is for posting pictures and decided to post one picture every Wednesday, at noon, which is the time and day that has the most viewers on Instagram.

Image 2: The best time to post on Instagram

When we started to think more about our target customers, people who will be attending our Pop-up Store, such as students and parents, my partner and I decided to make a product more suitable for these customers. So, instead of making teapots, we decided to make phone dock.

The idea to design a phone dock came to us when we noticed how OTIS students always wonder where they should put their phones when they are working on their projects. Therefore, designing a phone dock will not only be more practical but also attract people's attention.

From our sketches, we chose three ideations to make three

physical models (Image 6).

Image 6

We also had to manage the cost of the retail price, a

fundamental practice for product designers. (Image 7)

We continued to sketch and further develop our ideas (Image 8,9) and used cardboard for our mockup to speed up the ideation process. (Image 10, 11)

Image 9

Image 10

Image 11

Youtube: Mold Making

At this point, we were stuck trying to come up with an interesting design for the phone dock.

While my partner was staring at her phone, she wondered, "Why not make the phone dock tilted in multiple angles?" We proceeded to make our model, this time using foam (Image 12, 13).

Image 13

Having our product to be user-friendly is another aspect that we wanted to achieve. Since the thickness of individual phones varies, we tried a lot of different sizes so that all phones can be used in our phone dock (Image 14).

After a lot of failing, learning, and improving, we finally

made the perfect model, and we were ready to cast our mold (Image 15).

Image 15

In (Image 16), we are applying an All-Purpose Compound to

seal the foam mold.

Image 16

The cast molding is the most important step, so we spent a

lot of time on the model.

We plan to use the casting method to make 25 phone docks.

The first slip cast is currently in the kiln and according to our timetable,

the first finished phone dock will be ready in the next week.

To be continued 2 weeks.....

To be continued 2 weeks.....

- Frank Chiu -

0 comments :

Post a Comment

Thank you for commenting on O ZINE! It may appear soon.